Naval ship design

We deliver a wide range of complex engineering and design solutions with a heritage spanning defence organisations in Europe, the US, Canada, and the Pacific and a deep understanding of current challenges.

Our designers and engineers have the flexibility and capability to undertake the complete design and assurance of new naval platforms and introduce, execute, and manage design changes to existing in-service naval vessels.

We are the leading independent centre of excellence for naval design and through-life support in Europe and North America. One of the few external organisations named by the UK Ministry of Defence as a Delegated Naval Authority. We also undertake significant surface ship defence projects in Canada, Australia and Southeast Asia.

We pride ourselves on executing your requirements both within budget and on time. We are recognised for our experience, broad technical knowledge, long-term partnership management, impartial advice, and reliability.

We also advise acquisition agencies on balancing the capabilities of the ships they procure against the build, through-life operating and disposal costs. Our systems engineers and naval designers can make significant contributions from the first concept studies, through the detailed design phase to ship construction and ongoing in-service support.

Vessels we offer to the defence market include:

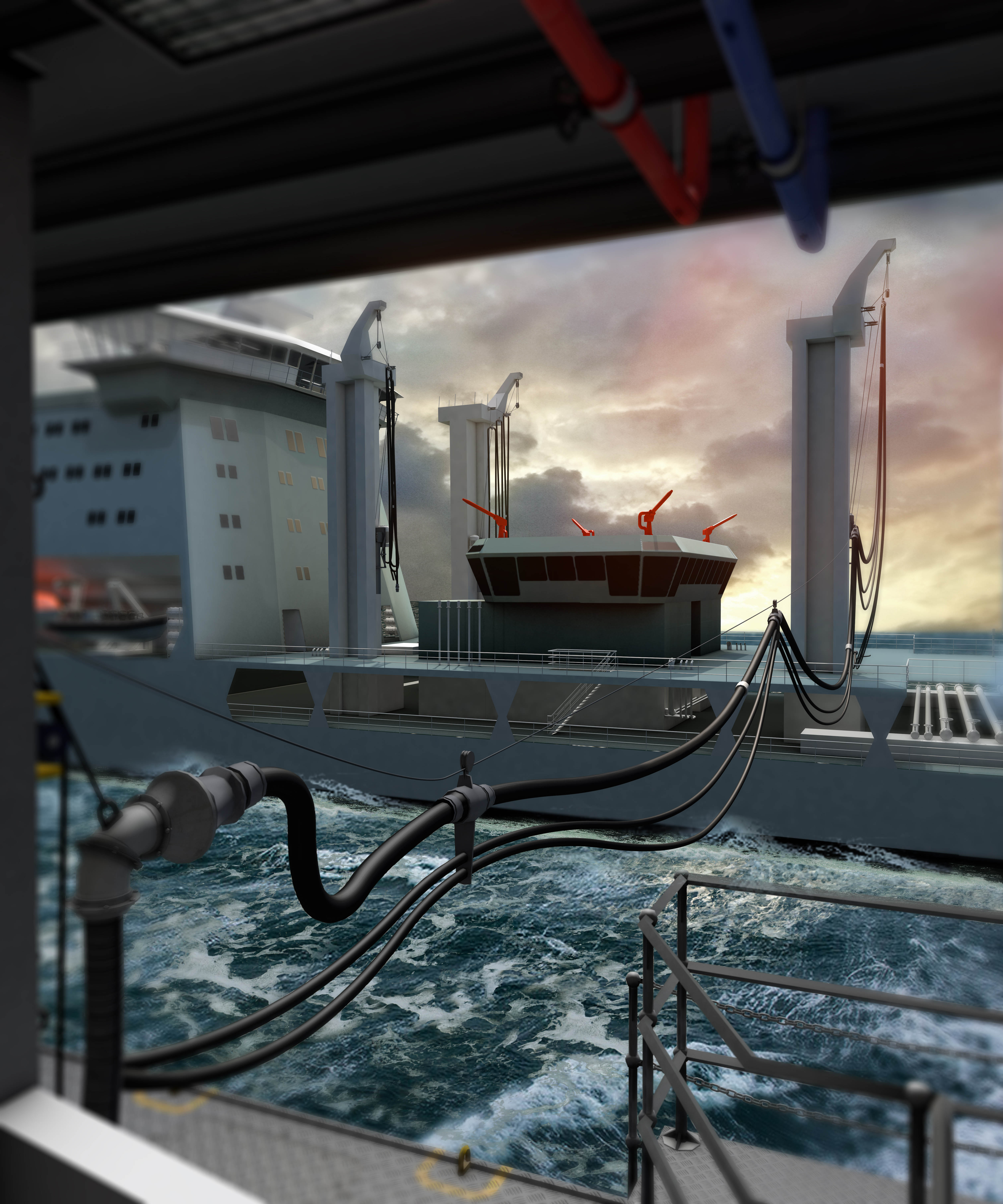

Our auxiliary range of vessels are designed to provide the capabilities to support global operations for naval and amphibious forces. Our extensive experience with auxiliary ships includes supporting the platforms operated by the UK Royal Fleet Auxiliary.

Our range of amphibious vessels has been developed to achieve cost-effective platforms whose capability offers improved speed, safety, and vessel design flexibility. More than a decade of investment in our CAIMEN™ family of landing craft has resulted in refined concepts that can be adapted to suit the requirements of military and security forces worldwide.

We leverage our expertise in high-performance craft design to meet the more robust requirements of the defence sector. Coast guard, navy, and law enforcement agencies benefit from vessels with significantly reduced motions in rough conditions while still retaining excellent safety, performance, and capability. Our investment in this sector has resulted in a range of operating vessels that include small, high-speed interceptor craft to large, high endurance mother ships.

Our technical, design and engineering skills mean that significant government agencies call upon us to support all aspects of platform design, upgrade, and life extension.

Getting a platform into service is not the only primary task: the real challenge and expense can come in keeping it ineffective service throughout its working life. We have substantial experience adapting platforms, either updating and maintaining current roles or evolving to suit different functions. We understand and manage the environmental and engineering challenges of the end of life and disposal processes.

Ensuring a platform is safe and meets naval standards through the life of a vessel is critical and requires enduring engineering knowledge and design capability, and class desks. We have in-depth experience in design support, engineering and technical expertise. We offer a centre of excellence that can augment government departments’ need to support Naval Material Assurance (NMA) and Ship Design and Acquisition Support (SDAS) of its fleets.