Sustainable coastal infrastructure

We provide vital consultant engineering services, including complete project management from conception to completion for marine, port, and coastal projects.

We have been involved in all areas of marine access, and terminal developments and marine and civil engineering and have extensive knowledge of the design, engineering and criteria for Container, General Cargo, and Ro-Ro terminals.

We have a wealth of experience in every aspect of marine access and terminal developments, and marine and civil engineering.

From building jetties to prototyping new offshore communities, we design and manage the construction of coastal structures and help you overcome complex technical challenges.

We provide a detailed design service that complies with international codes, project management, design review, and value engineering.

From building jetties to prototyping new offshore communities, our expertise in designing and managing the construction of coastal structures can help you overcome the complex technical challenges of such projects.

We have extensive experience in feasibility studies for ferry and cruise terminals. Our expertise covers financial and marine feasibility, terminal layout, and ferry concept design for new developments or existing terminals. We can also assist our clients in developing short, medium, and long term masterplans to achieve the most technically viable and cost-effective solution.

We provide innovative and cost-effective solutions to aid the design of breakwaters and jetties. Our experience includes:

We have extensive experience designing various types of solutions for ports handling containers, general and Ro-Ro cargoes for quay walls and wharf structures. Our services cover:

We focus on the same skills, tools, experience, and understanding of the coastal environment for ports and terminals to inform modular floating platforms and other offshore and waterfront infrastructure.

We offer customised solutions for public, industrial and high-end infrastructure to address land scarcity and specific project requirements. Our services range from feasibility study, concept & detailed design, construction supervision and testing & commissioning. Our experienced team of naval architects use industry standard tools to deliver engineering designs including structural design, stability analysis and mooring analysis.

Industrial and logistics parks play a pivotal role in global manufacturing and trade. We offer planning support catered to the customer needs - from strategic positioning, identification of target industries, cargo hinterland competitiveness and value chain analysis to sector demand for industrial land area, master planning, zoning and product mix solutions. We identify, create and optimise business models and investment plans for industrial parks, logistics and free zones, as well as defining marketing and commercial strategies to achieve an integrated port, park and trade infrastructure development.

We regularly provide project management for marine facilities, including some of the world’s most significant port projects and cover the entire lifecycle of a project from a concept from concept to commissioning.

Our services encompass contractor choice, construction methodology, site supervision, programming, planning, contract management and quality control. In addition, we can develop a project management service to cover the entire lifecycle of a project, from concept to commissioning.

Our experience includes:

"What we like most about BMT is their understanding of our needs, their flexibility, and the high quality of the results they deliver. I look forward to working with BMT again soon."

Modern Terminals Ltd, Hong Kong

We study the external and internal risk factors of marine facilities as well as consequences. We review navigation, search and rescue problems, the port marine safety code, and assessing and auditing safety management systems.

We examine the project issues and risks and advise on the most appropriate ways of mitigating them. We look at what impact a project’s vulnerability and risk may have on businesses or countries and advise on the most appropriate ways of mitigating that risk.

We use our cartography and drafting capabilities to think quantitatively and make better decisions based on data and analysis.

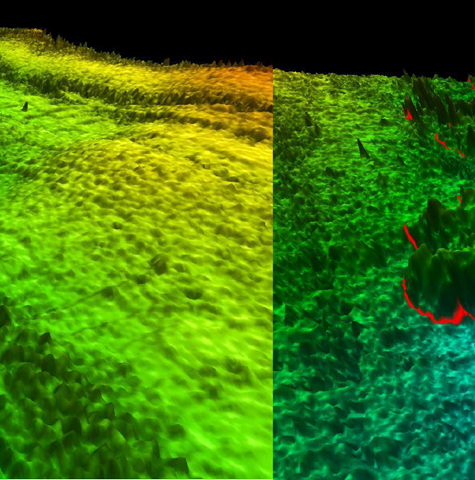

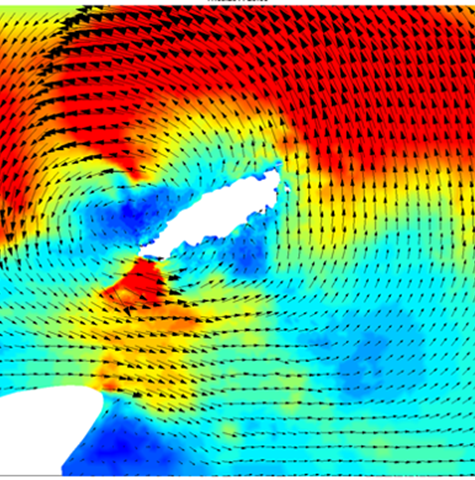

TUFLOW has have become an industry standard for modelling coastal environments, enabling you to gain greater predictability, certainty and confidence.

Our understanding of the metocean processes and conditions that influence the design and operation of marine infrastructure is based on extensive experience in the industry.

We use in-house historical metocean databases, numerical modelling, and analysis to inform the criteria for operations, preliminary design, front end engineering design, mooring layout design and breakwater and terminal design, including coastal erosion modelling and coastline evolution under the influence of shoreline recession and sea-level rise.

IAPH is a non-governmental organization (NGO) aiming to be the global trade association of choice for port authorities and operators, representing their interests at a regulatory level at the International Maritime Organization, the World Customs Organization, the International Standards Organization and other global alliances such as the Global Maritime Forum and the World Economic Forum.