There is no prescribed methodology for demonstrating that necessary control measures are actively managed to ensure risks are reduced to ‘As Low as Reasonably Practicable’ (ALARP). However, several basic approaches may be used to support the provision of evidence and justification. An ALARP demonstration can be justified in several ways: navigating regulatory requirements by focusing on the relevant and applicable local and international legislation, regulatory guidance, codes and standards or through sound engineering judgment.

The approach ensures robust decision-making by applying engineering scientific principles and methods.

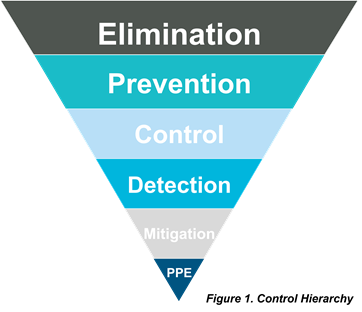

Engineering judgement should follow the hazard management hierarchy in the decision-making process for critical safety decisions. The hazard management hierarchy requires a focus on inherent safety principles, as shown in Figure 1.

Where feasible, inherently safer solutions produced by eliminating or preventing a hazard are always preferred over other engineering controls. These are also preferred over administrative or procedural rules which rely on human interactions.

ALARP Decision

A vital element of the ALARP demonstration is ensuring that no other practical measures can reasonably be taken to reduce safety risks further. Efforts should be targeted at the significant risk contributors associated with a facility or activity.

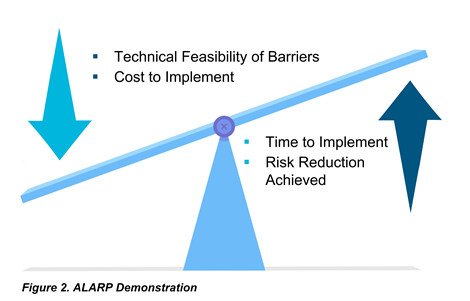

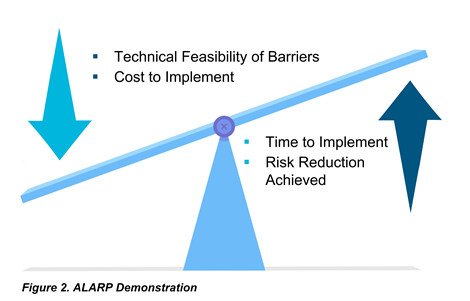

Potential additional control measures should always be evaluated in terms of technical feasibility, cost, time to implement, and risk reductions achieved, as shown in Figure 2, to ensure the trade-offs in the decision-making process are understood.

Our Approach

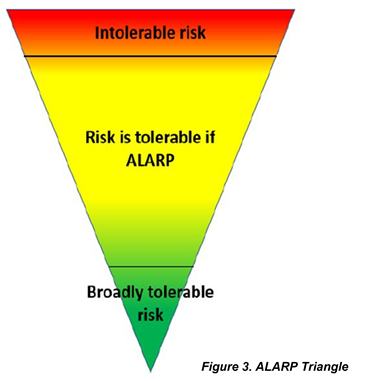

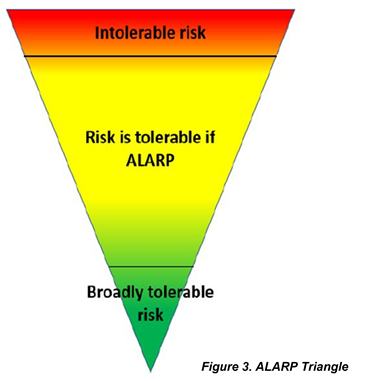

There is no silver bullet for demonstrating the necessary control measures that have been and will continue to be identified to reduce risks to ALARP. We use the following approach, which can be used in addition to other methods, determined by the nature of the facility and the scenario. The ALARP triangle, shown in Figure 3, demonstrates the decreasing of risk and the diminishing proportional benefits of risk.

We consider the following approaches to demonstrate ALARP:

-

Risk Criteria-Based Approach: In this approach, the company or regulatory risk tolerability targets are assigned, and ALARP is shown by comparing against them.

-

Cost-Benefit Analysis (CBA): A numerical assessment is performed on the costs of implementing a control barrier or modification and the likely reduction in fatalities that would be expected. Also, criteria on the value of a life or the actual cost of averting a statistical fatality (ICAF) are considered. There is no simple cut-off, and additional factors, including uncertainty, must be considered in the decision-making.

-

Qualitative Approach: A combination of various practices is assessed in this approach, including comparing against industry-specific codes and standards, audit against good practices, technical analysis, and performance data on the operational effectiveness or the reliability of a control measure.

-

Engineering Judgement: In this approach, as the name suggests, we consider if the engineering judgement has sufficient controls in place, the nature of the rules are within parameters, and their position is relevant. Similarly, passive measures are more suitable than active engineering measures, which shall be considered better than administrative or procedural controls.

Our Role

We have experience preparing ALARP demonstration reports for all types of facilities and offer safety and risk solutions to overcome safety and regulatory challenges.

Client A: Chemical Production Facility

ALARP Demonstration example: Gap analysis with relevant codes and standards (Qualitative approach)

The existing chemical production facility had to undergo an ALARP demonstration to meet the new local safety case regulations. Because of the complexity of the facility, a qualitative approach was adopted for the ALARP demonstration. As part of this approach, a gap analysis was performed against applicable industry codes and standards (e.g., API, ISO, and RP) to identify areas for improvement in the existing control barriers and design principles. Following the gap analysis, a brainstorming session with all stakeholders was conducted to assess how the identified gaps should be addressed and implemented to schedule. We recommended that the overall requirement for evidence of ALARP applies equally to operations, ongoing maintenance, and turn facility design and construction programs.

Client B: Onshore Storage Terminal

ALARP Demonstration example: Combined approach

A Major Accident Event (MAE) scenario was assessed as a high risk against the company’s risk matrix. A combined approach was adopted for this scenario; initially, existing control barriers were evaluated based on a qualitative approach, then assigned risk tolerability targets per company tolerance criteria. A Layer of Protection Analysis (LOPA) was applied to identify initiating events and calculate the residual risks to determine the amount of risk reduction required to bring the chance to ALARP. BMT assigned the Safety Integrity Level (SIL) to this barrier and proposed to install a SIL1 system to demonstrate ALARP. Based on the detailed review of the system, an independent level switch or transmitter was recommended, which would provide an alarm to a control room and independent operator such that procedural action can be taken.

Conclusion

This technical article has discussed how various approaches can demonstrate ALARP for a facility or specific activity. The report provides a proven structured framework for ALARP demonstration for how an organisation manages safety and should guide future decisions around selecting and assessing control barriers.