30 November 2023

As the global maritime sector faces mounting pressure to reduce greenhouse gas emissions, BMT and PA have delved into alternative fuels for decarbonisation. This study focuses on the potential of one of these fuels, hydrogen, as a low-carbon alternative for Ro-Pax ferries. The objective is to assess the economic and technical feasibility of retrofitting existing vessels with hydrogen propulsion systems, presenting three retrofit alternatives with varying complexity, hydrogen demand, and costs.

The transport sector's imperative to reduce emissions resonates strongly within the maritime industry, responsible for approximately 11% of global CO2 emissions. Ro-Pax ferries alone contribute 37 million tonnes of annual CO2.

Dr. Thomas Beard, Senior Analysis Engineer at BMT and co-author of the industry white paper unveiled at the Marine Log's 36th Annual FERRIES Conference in the New York City area on November 14th and 15th, 2023, shared insights, stating:

“The recently launched white paper, 'Feasibility of retrofitting medium-sized Ro-Pax ferries to utilise hydrogen propulsion and storage technology,' delves into the challenges and opportunities unique to the maritime sector. The study, introduced earlier this month at Marine Log's 36th Annual FERRIES Conference, underscores the urgent need for tailored solutions within this dynamic industry.”

“The requirement to meet Net Zero will require a change in fuel, as such BMT are exploring several options to support the maritime transition onboard vessels. However, the total cost of ownership (TCO) is an important aspect and collaboration with PA allows the techno-economic facts to be fully explained.”

The white paper employs an 85-meter Ro-Pax catamaran as a case study, analysing the vessel's characteristics, operational profile, and potential for retrofitting. The vessel's size, speed, and operational frequency make it an ideal candidate for transitioning to hydrogen propulsion. The study considers three retrofit options, incorporating technoeconomic modelling to assess costs and benefits.

Lee Hedd, Regional Sales Director for BMT in North America and Canada, adds:

"I am thrilled to be part of our collaboration with PA, showcased at The International Workboat Show 2023. BMT, with a rich history of addressing complex engineering challenges, is committed to delivering innovative solutions. Our joint effort with PA, focusing on retrofitting Ro-Pax ferries with hydrogen propulsion technology, exemplifies our dedication to pioneering sustainable advancements in the maritime sector. This study not only explores alternative fuels but underscores our team's capability to tackle the unique challenges of decarbonisation. We're excited to present our findings and contribute to shaping the ‘design’ future of environmentally responsible maritime transport."

Mike Davis, energy transition expert at PA Consulting, says:

“The need to identify credible decarbonisation pathways in the maritime sector is more pressing than ever, and we need to start looking closely at the various practical decarbonisation solutions that are available. Our aim for this study was therefore to move beyond high-level analysis and present a detailed technical and economic assessment of a realistic low-carbon retrofit option, considering an example vessel in operation today. This allowed us to get right to the heart of some of the key questions that we’re hearing from the sector as it looks to adopt low-carbon fuels, such as the quality of the business case for vessel operators, realistic expected emissions reduction benefits, and the detail around key technical challenges. We’re excited to discuss the outputs with the industry and explore how we can collectively accelerate the uptake of decarbonisation solutions across a range of fleets and vessel types.”

Hydrogen Technology Review

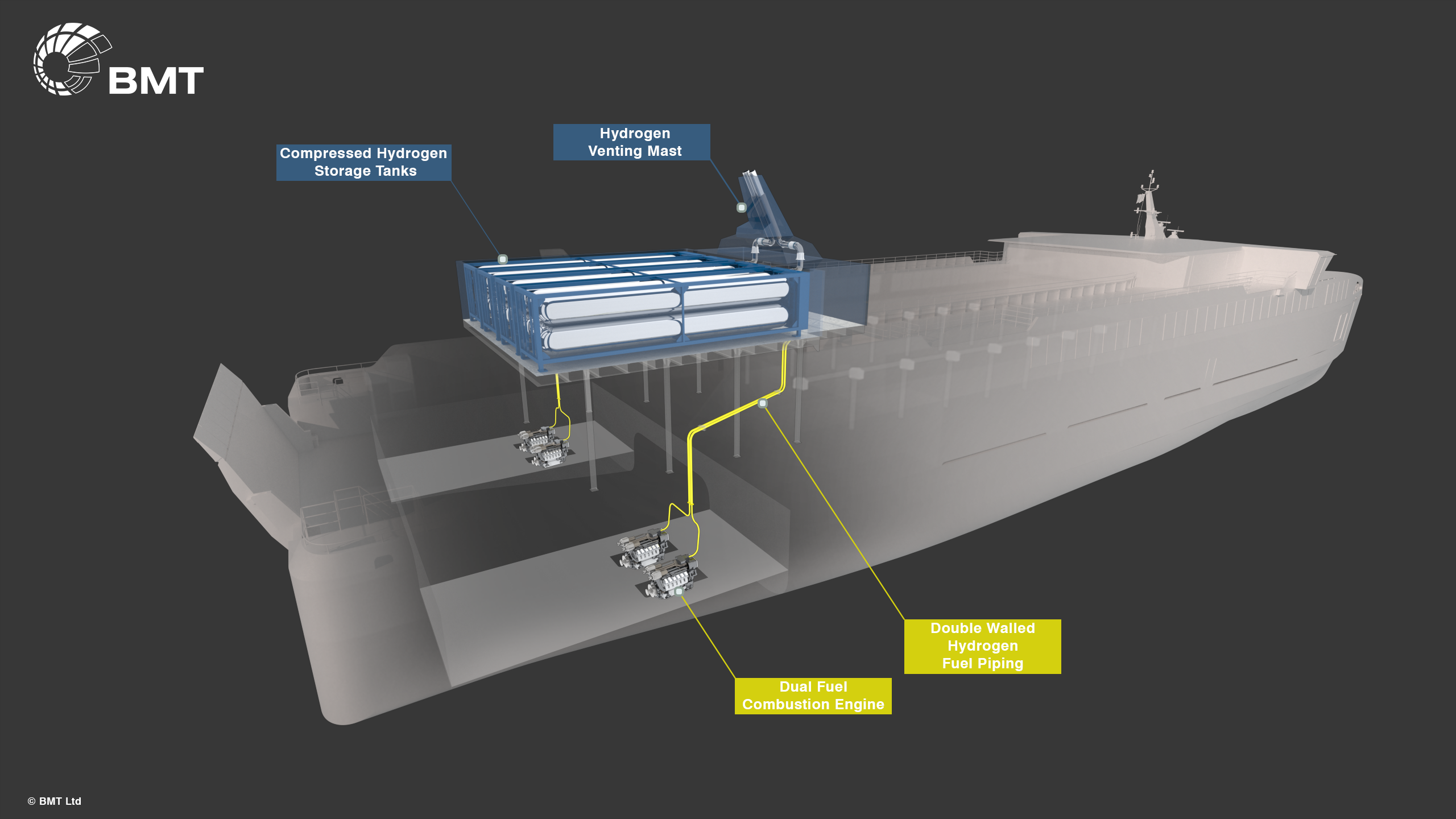

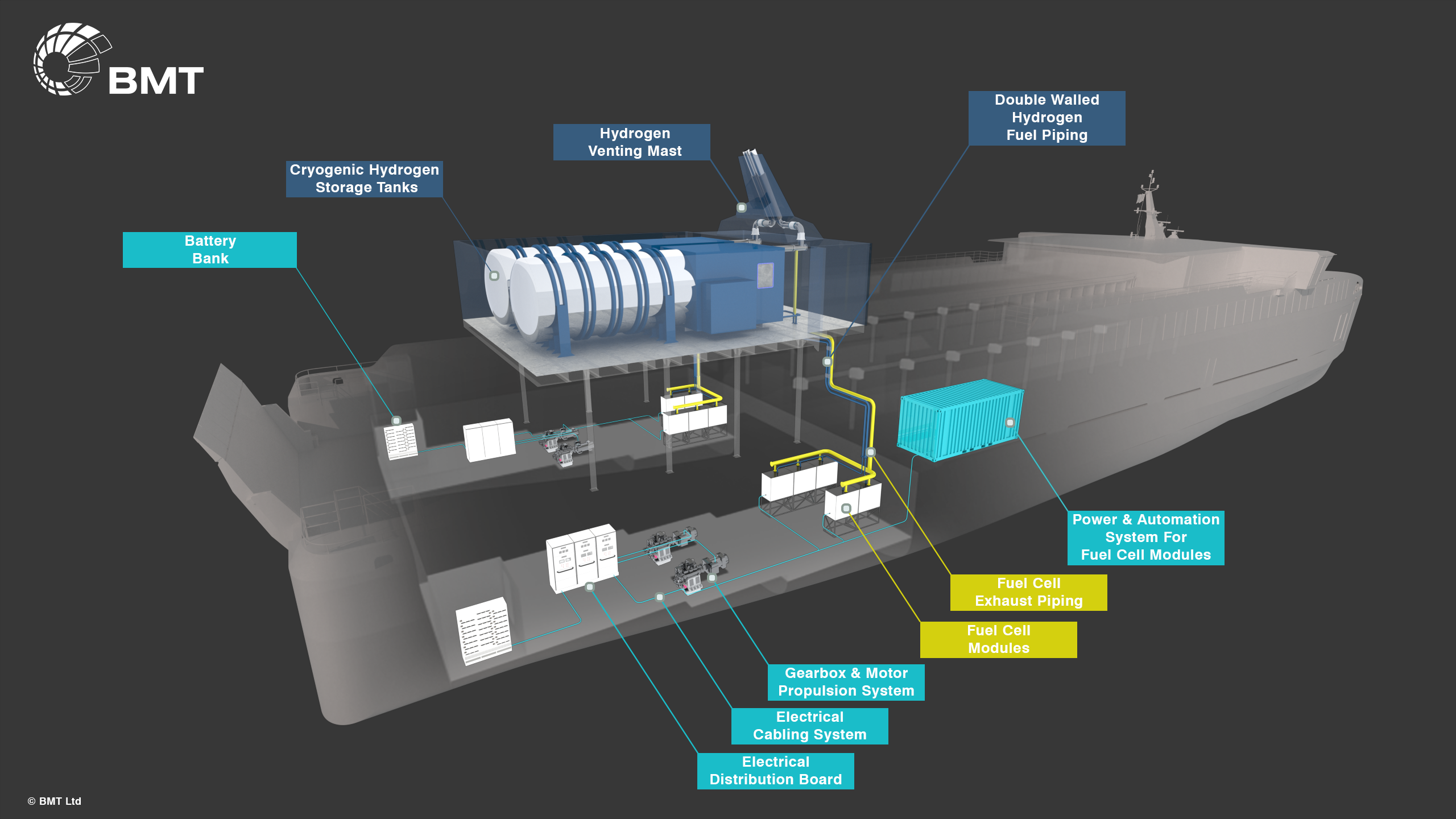

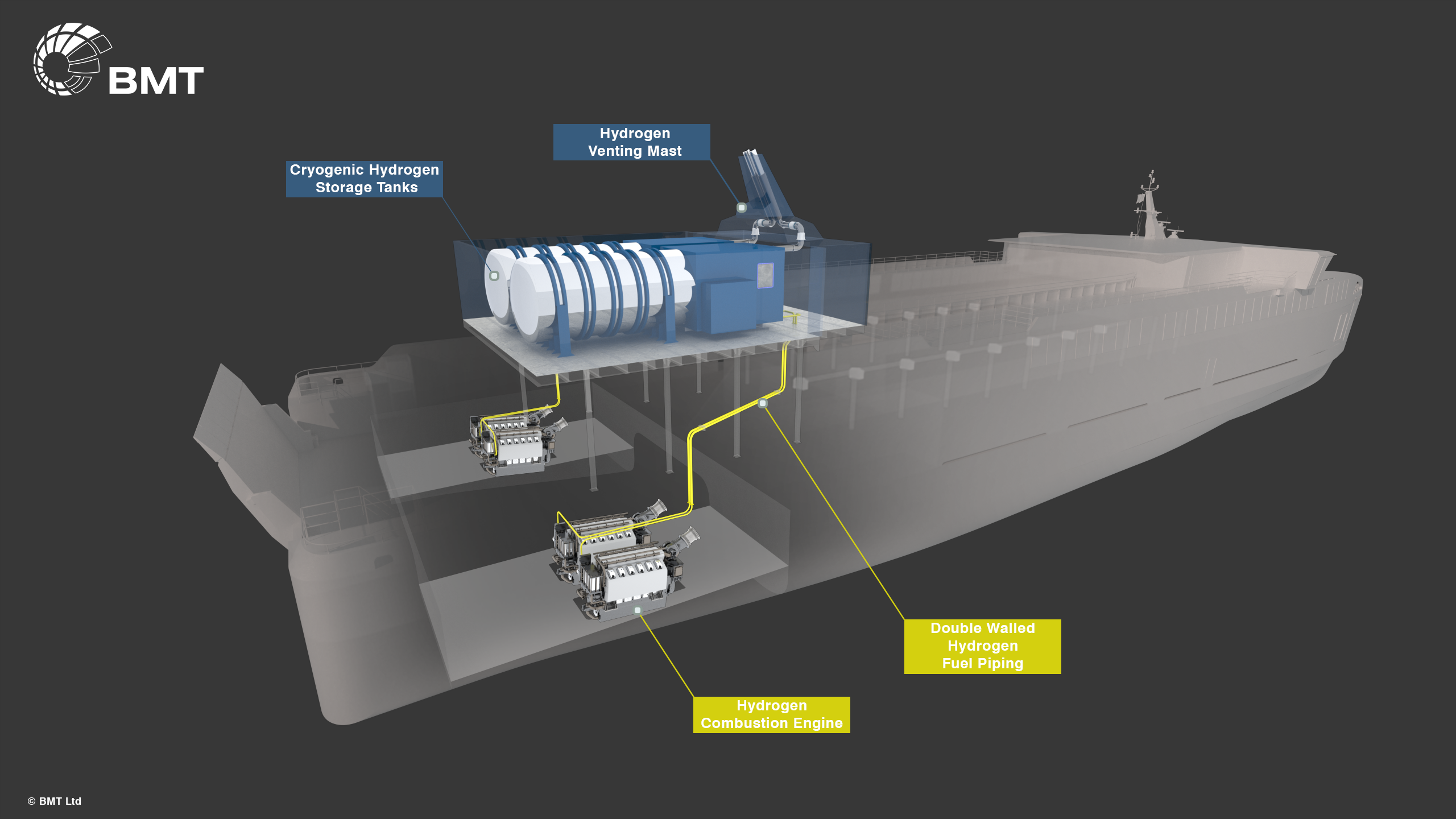

The study provides a comprehensive review of hydrogen production pathways, focusing on green and blue hydrogen. It explores various hydrogen propulsion options, comparing fuel cells and internal combustion engines. Onboard hydrogen storage options, including compressed and liquefied hydrogen, are analysed, considering factors such as space, safety, and retrofit challenges.

Retrofit Options

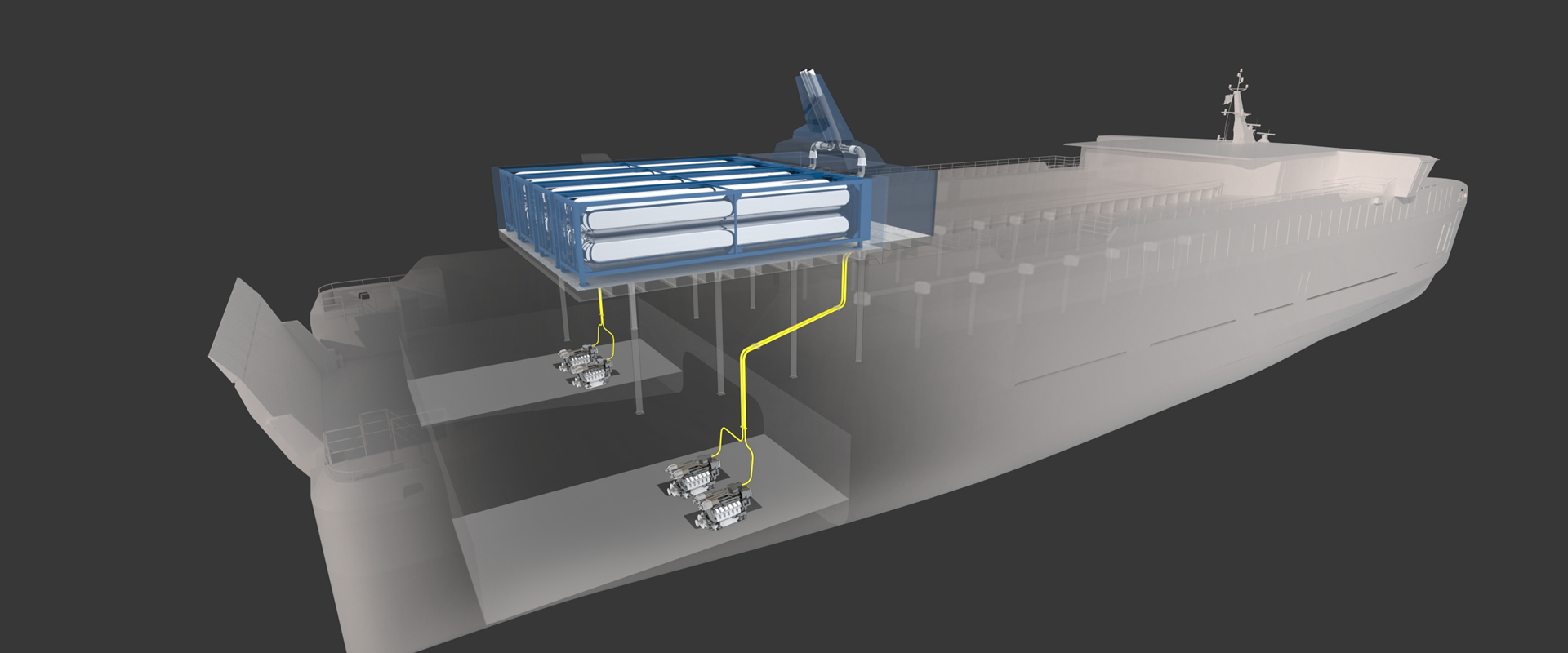

The white paper introduces three retrofit options, each addressing specific challenges and presenting unique advantages. These options involve dual-fuel engines with compressed gaseous hydrogen storage, hydrogen fuel cells with liquefied hydrogen storage, and internal combustion engines running on 100% hydrogen with liquefied hydrogen storage.

Long Distance Scenario

A critical factor in the study is the availability of hydrogen for refuelling across the vessels operational profile. The analysis considers scenarios where hydrogen is produced both locally and offsite, assessing the impact of transportation on total cost of ownership (TCO). The study underscores the importance of minimising hydrogen transportation distances for economic viability.

Cost analysis

The study evaluates the levelised cost of hydrogen (LCOH) for different production methods, comparing blue and green hydrogen, and assesses this against the fuel cost for marine gas oil (MGO). The additional impact of subsidies on the cost of hydrogen fuel is also assessed. This is combined with an assessment of the capital cost of conversion and other OPEX to assess the total cost of ownership over the vessel lifetime.

The white paper concludes that hydrogen fuel cells offer a cost-effective propulsion solution for the studied vessel on a total-cost-of-ownership basis over its lifetime when compared to continued use of MGO. The analysis also shows that while costs for low-carbon fuels are currently higher than fossil alternatives, factors such as technology advancement and carbon pricing are expected to drive down this cost differential in the coming years. The study emphasises the need for subsidies, strategic co-location of hydrogen assets, and ongoing advancements in hydrogen technology for long-term viability.

The collaborative effort between BMT and PA provides a close look at the engineering feasibility of various hydrogen propulsion systems, emphasising the importance of fuel flexibility, emissions reduction, and efficiency. The study acknowledges the challenges of integrating hydrogen technology into existing ships but underscores the potential benefits for decarbonisation.

The white paper also incorporates detailed modelling of the cost of hydrogen production over a typical vessel lifetime. The model considers techno-economics, hydrogen production pathways, and government policies, tailoring the analysis to the vessel's operational requirements.

The collaborative white paper by BMT and PA, titled 'Feasibility of retrofitting medium-sized Ro-Pax ferries to utilise hydrogen propulsion and storage technology,' premiered at this year’s International Workboat Show. It's now available for exploration, find download below.

Fill in the form below to request further information about our latest research into Retrofitting Ro-Pax Ferries with Hydrogen Propulsion.

29 November 2023

Our latest 42m (140ft) all-electric ferry design concept has been unveiled in New Orleans, at International Workboat Show.

2 March 2023

We are pleased to announce that our latest 27m CTV hybrid vessel design showcasing our patented BMT Active Fender System® and hybrid propulsion system has been selected by HST Marine for the European offshore wind industry.

2 March 2023

On the first day of the Dubai International Boat Show, Oceanco revealed a revolutionary yacht design: Aeolus. Fully aligned with Oceanco’s NXT initiative, Aeolus is in tune with evolving perspectives on the environment as well as lifestyle.