Heavy machinery lifecycle and design

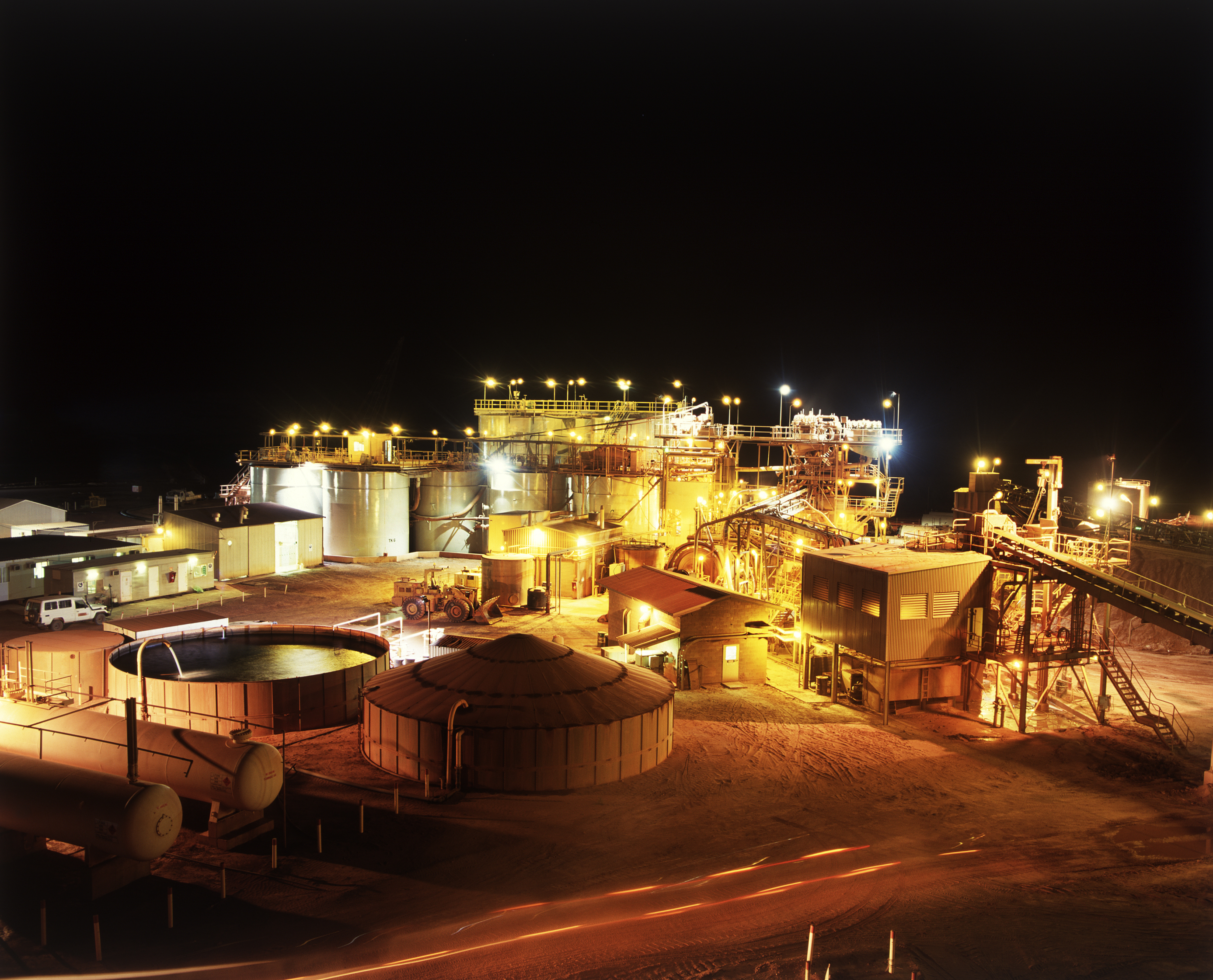

We have built a reputation for excellence by designing advanced, innovative mining machinery that helps extract commodities more efficiently while increasing safety and environmental protection.

Surface and underground mining operations depend on machines that can deliver high productivity levels - and do so reliably. But we understand that these must constantly evolve to meet changing market and regulatory needs in an industry with a long heritage of innovation.

We re-design and engineer existing devices to improve performance, increase capacity or reduce risks.

Whatever the application, we can manage the entire process, from concept development to final commissioning, or provide support for a single aspect.

We provide ‘win-win’ solutions that increase machine and operator safety as well as productivity, and we offer a range of expert in-house capabilities that include:

We help maximise the reliability of new systems by preparing and contributing to detailed technical specifications. We specialise in writing concise technical specifications to define the standard against which you can audit the machine and the procedural rules for conducting the audit.

We can help you get the most from the mineral processing equipment by providing design capabilities for specific new machinery, including grinding mills, vibrating screens and centrifuges. We also have extensive experience re-designing and engineering existing machines to extend their service life and reliability.

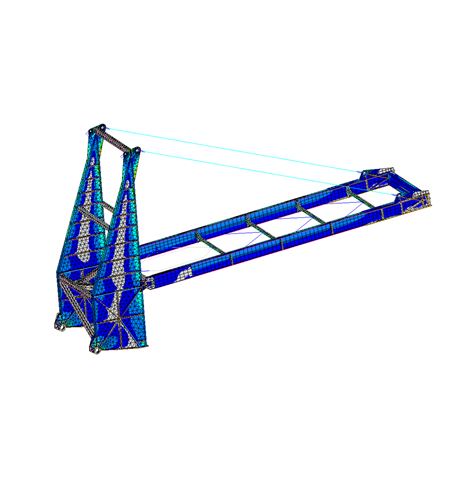

The analysis is a critical element of the overall approach to solving problems in large machinery.

It is an integral part of the design, troubleshooting, failure analysis, performance enhancement and life extension services.

We use mathematic models to help you predict situations and make critical decisions. We use leading-edge software and computing hardware to provide rapid answers to complex problems involving stress and fatigue analysis; fluid flows, heat transfer, structural and drive dynamics and control systems.

Our design audits help you improve safety, extend structure and machinery life, verify conformance with specifications and identify operational risk.

We specialise in fast-track audits, which are run parallel with the machine's original design, allowing you to find and correct design deficiencies and errors. We conduct design audits on most major plant and machinery types, enabling you to unlock productivity gains safely.

Our expertly designed conveyors and conveyor systems help you extract and move commodities rapidly, efficiently and safely.

We help to keep vital machinery bearings running smoothly and for longer. With over 25 years' experience in the testing, assessment, troubleshooting and re-design of large rolling element bearings, we can offer you a unique service, including accurately predicting probable bearing life as well as extending it through the specification and design of upgraded bolt-hole compatible bearings. We also advise bearing change-out procedures and support techniques for increased bearing life.

By using radio telemetry systems to transmit data on the performance of rotating machinery, we help you diagnose and prevent problems, adjust maintenance schedules, and extend machinery life. Our specialist technology can monitor and transmit torque/torsional vibration, speed (and hence power), strain/stress and vibration on all types of rotating machines.

We have a long history of designing and adapting shovel machinery and dragline maintenance and support operations, and it's that experience that drives the design of innovative features such as real-time feedback and sophisticated diagnostics.

We help improve stacker performance by assessing and re-designing your mechanical, structural and electrical systems, then performing accurate site testing using strain gauges and sensors to measure your machines' motions, stresses, and loads at every phase. With a clear and precise view of your stacker performance and requirements, you'll be able to maximise productivity from your machinery while staying within safety limits.

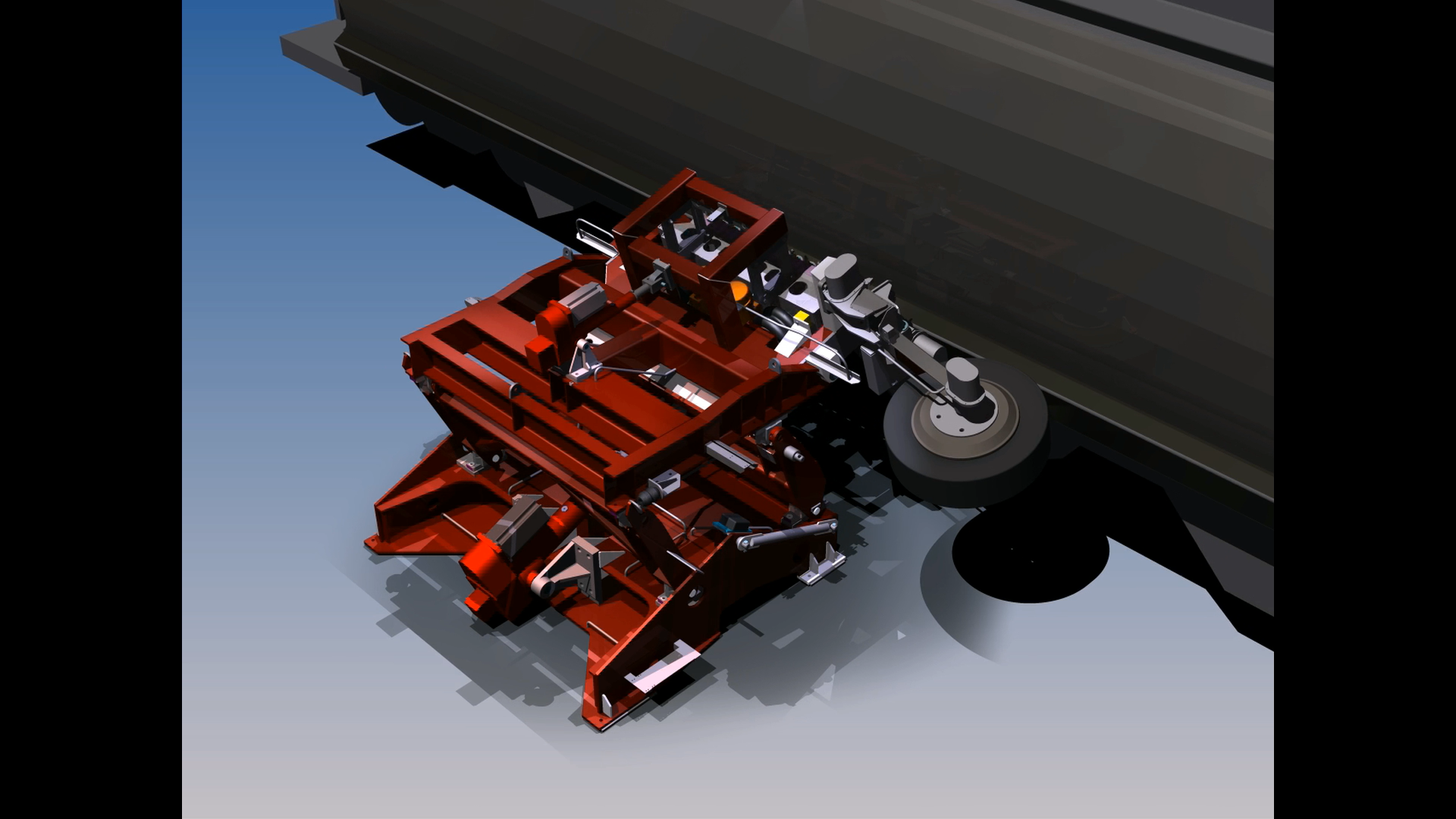

We excel in designing advanced and highly specialised machines to suit the specific needs of your mine or process. Whatever the application, we can integrate the necessary skills to develop an efficient engine that delivers what we call 'smart productivity'.

The ability to weigh large machines is crucial to plant operators to confirm total mass and centre of gravity location under all cross travel, luff and slew settings. Yet carrying out this measurement can be challenging. We use load cells, pressure transducers, and displacement transducers to overcome this challenge and help customers accurately weigh draglines, bucket wheel excavators, stacker-reclaimers, and ship-loaders.

Thanks to our work with haul truck operators and manufacturers, we have a wealth of experience in designing, testing, and analysing truck frames and bodies, drive trains, and suspension units, which we apply to help you improve vehicle performance and site productivity.

As recognised authorities on bucket wheel excavators, we're perfectly placed to help design systems that deliver to the highest safety standards, particularly in challenging digging conditions such as lignite mines.

The design of any lifting tackle must be completed to relevant international standards and include the required design margin. We have relevant experience in lifting tackle systems design for many plant items, using the suitable combination of off the shelf components and our in-house designed items such as spreader beams. This experience includes the compilation of lift plans and studies, supervision before and during the lift, and quality assurance aspects such as inspection and test plans.

Roof support design plays a crucial role in underground mines' safe and continued operation. We can help you adapt plans to prevent early failures and ensure safe operation by accurately measuring and modelling operating loads and stresses.

Our experienced expert teams can support your mineral processing, helping you with everything from initial concept to detailed design, including mechanical, structural, hydraulic, electrical control, drafting, fabrication surveillance, installation and commissioning.

Effective gearing is crucial to nearly all mining, materials handling and mineral processing machinery. We support all aspects, from designing gear trains and gearboxes to driving measurements and failure analysis. We also carry out torsional vibration analysis of geared systems and the rating of gearing according to international standards. Our radio telemetry systems are used for in-service torque, torsional vibration and power measurement and confirmation, as well as troubleshooting, including twin drive load sharing.

We provide a full range of expert engineering services to operators and manufacturers of mills, centrifugal fans, and cooling towers to help maximise productivity while maintaining high levels of safety and regulatory compliance. We help you benefit from a clear view of‘ smart productivity’ from fatigue analysis to design audits and troubleshooting.

We provide a full range of expert engineering services to operators and manufacturers of vibrating screens to help maximise productivity while maintaining high levels of safety and regulatory compliance. From concept and detailed design to fatigue analysis, design audits and troubleshooting, we support all types of vibrating screen equipment, including single, multiple, flat and banana decks.