Highly efficient materials handling for mines and ports

We have a global reputation for designing bulk materials handling systems that transfer commodities such as coal and iron ore quickly and safely, day in and day out.

We have built a worldwide reputation for designing bulk materials handling systems which help you get commodities such as coal and iron ore out of the mine and onto vessels more quickly and safely, day in day out.

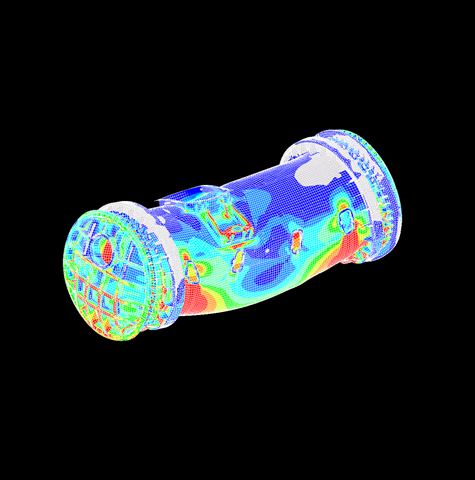

We use specialist design tools to undertake finite element analysis, computational fluid dynamics, discrete particle modelling, fatigue and conveyor analysis. We provide an efficient and reliable assessment of problems, supported by software specially developed in-house to carry out complex, state-of-the-art studies for conveyor dynamics.

In summary, we work with you to understand your exact requirements.

The range of solid bulk cargoes is considerable and ship types may vary from dedicated bulk carriers to general cargo vessels, inland barges and an extensive range of coasters. Many solid bulk cargoes are classified under the International Dangerous Goods Code for Solid Bulk Cargoes (IMSBC Code) and, therefore, require special attention during loading, transportation, and discharge.

Our services include:

We help you optimise the performance of equipment such as bucket-wheel excavators, stackers, reclaimers, ship loaders, ship unloaders, conveyors and conveying systems, mills, crushers, screens, draglines, and mining shovels. We offer a complete service from initial investigations and machinery design to project management, specialist electrical services, procurement, and technical support.

We provide a comprehensive range of specialist studies and design services, from concept development to fully detailed design. In addition, we have specialist material handling system capabilities to assess performance, reliability and maintenance, access, and system flexibility.

We also assist with capital and operating estimation, life cycle cost estimation, system control philosophy design and system simulation and modelling. We use specialist design tools to undertake finite element analysis, fluid dynamics, discrete particle modelling, fatigue, and conveyor analysis.

We provide an efficient and reliable assessment of problems, supported by our own proprietary software to carry out complex analyses for conveyor dynamics. We’re deeply experienced with the commercial and industrial aspects of port equipment, from ship loaders and unloaders to grab cranes and passenger gangways, and we offer quality engineering services that benefit day-to-day, short-term, and long-term operations, from design to advice.

To achieve this, we provide complete design capabilities for new bulk handling systems and related machines such as bucket wheel excavators, and we have extensive experience in redesigning existing devices to extend service life and reliability.

Whatever the application, we can support any single aspect or manage the entire process, from concept development, detailed design and manufacture to installation and final commissioning.

We unlock the ‘win-wins,’ where machine and operator productivity increase alongside machine health and operator safety.

Our in-house capabilities include:

Transfer chute problems are often a consequence of poor design and lost production. We help you address the issues by fusing our design expertise and extensive on-site experience with advanced analysis. We provide a complete range of engineering, design, and analysis services that improve transfer chutes and maximise transfer point performance for fewer chute blockages and increased output.

We use specialist design tools to undertake finite element analyses, computational fluid dynamics, discrete particle modelling, fatigue, and conveyor analysis. We provide an efficient and reliable assessment of problems, supported by our own special proprietary software to carry out complex, advanced studies for conveyor dynamics.

We help maximise the reliability of new systems by preparing and contributing to detailed technical specifications. We specialise in writing concise technical specifications to define the standard against which you can audit the machine and the procedural rules for conducting the audit.

We can help you get the most from the mineral processing equipment by providing design capabilities for specific new machinery, including grinding mills, vibrating screens and centrifuges. We also have extensive experience re-designing and engineering existing machines to extend their service life and reliability.

We help you successfully deliver materials handling plant systems that meet the demanding performance requirements of mine and port facilities. We help you unlock every opportunity to increase productivity while maintaining strict safety and environmental standards. We do this at every stage, from using sophisticated modelling tools to aid initial design, to managing construction, installation, and commissioning. Our innovative approach to materials handling design is supported by our unrivalled practical global experience.

We use our expertise in designing conveyors and conveyor systems to help you move commodities quickly, safely and efficiently, while our innovative design features can improve conveyor availability and reliability and reduce downtime. Whether designing a new system or modifying an existing one, we use sophisticated conveyor analysis tools alongside our extensive troubleshooting and testing experience to help you deliver ‘smart productivity’.

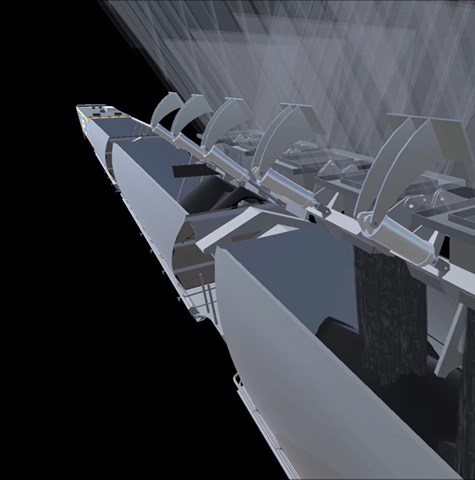

We can help you design, adapt, and operate materials handling systems for self-unloading ships. We can design the entire materials handling plant, including the mechanical, structural, electrical and control details for conveyors and bucket wheel reclaimers. And to ensure maximum benefit from our plans, we can supervise the plant’s fabrication, construction, and commissioning.

Finding better ways to move bulk materials onto ships is key to improving productivity. Our innovative approach is built on practical experience in creating new or revised designs that deliver results. Our expert mechanical and electrical design services help to increase performance while also achieving high environmental and safety standards, and we provide comprehensive, independent structural design reviews that include primary and secondary structures and all critical mechanical connections affecting the strength and stability of the plant.

We offer an extensive range of tailored management tools and techniques to help make better decisions about your marine, energy and defence assets.

We have built a reputation for excellence by designing advanced, innovative mining machinery that helps extract commodities more efficiently while increasing safety and environmental protection.