Through life engineering solutions

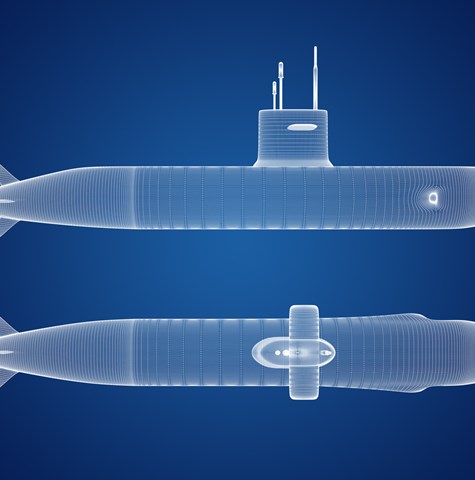

We provide integrated logistics support across a range of engineering and technical domains to support pre and post-delivery for new or modified ships and submarines.

Key contact

Business Development Manager

If a vessel or asset isn’t operating or is difficult or costly to maintain, it’s a drain on organizational resources.

In many cases, downtime due to maintenance, repair or other activities can be accounted for. In other circumstances, unplanned failures can occur which threaten to upend even the most carefully planned operations. In all cases, a holistic view of a fleet’s lifecycle can help you understand, plan and carry out sustainment work in a way that maximizes availability and operational performance.

We offer real-world, practical knowledge of the best practices used by commercial and government fleets. We’ve developed and implemented fleet lifecycle management and integrated logistics (ILS) programs that have delivered measurable results in asset availability, maintenance hours and failure rates. We build in well-documented systems, processes and tools that continuously drive improvement, keep RAM considerations at the core of acquisition and design, and deliver new efficiencies and value. We can deliver ILS and support services for new acquisitions and work within existing systems and assets at any point in their life cycle.

Our lifecycle management capabilities include:

Our deep technical understanding of complex legacy platforms across all naval platform design disciplines sees us recognised by many of the world’s navies as experts in design change. We support, maintain, and improve naval platforms from life extensions to complex capability upgrades and combat systems integration. The aim, as always, is to facilitate design change that supports a high level of fleet time availability and operational readiness through affordable and timely solutions.

We apply engineering and analytical tool expertise to a submarine’s structural and mechanical systems throughout its life. Our damage assessments also consider the age-related degradation effects and long-term fate of issues from corrosion and mechanical damage to vibration, cracking, fabrication and design faults:

We help our customers realise performance, availability, reliability, cost and schedule improvements through effective maintenance management systems. Our management and consulting abilities help you develop, implement, execute and sustain these systems at a fleet and specific vessel level.

As well as on-site Port Engineering or Availability Project Management for vessel construction and modification, we support maintenance management in two key ways:

Our deep technical understanding of complex legacy platforms across all naval platform design disciplines allows us to understand and develop disposal or sales solutions as platforms reach the end of their useful life.

From disposal or developing design change solutions to enable selling on a platform to another user or developing end-of-life disposal solutions (e.g. Green Passports), our engineers bring a comprehensive range of skills to deliver affordable and timely solutions.

We specialise in the mathematical modelling and simulation of engineering problems, which helps you safely and accurately assess operational issues before implementation.

The ability to accurately monitor the performance and impact of abandoned or deteriorating assets is essential during their decommissioning.

We evaluate the suitability or interaction of materials to support design, maintenance, and investigations.

We are world leaders in managing reliability and retaining or restoring your technical assets to the necessary condition when carrying out maintenance.