How is Risk Calculated?

As an already well-established company in Singapore and a National Environment Agency-approved Quantitative Risk Assessment (QRA) consultancy, we ensure that our customers take a thorough approach to risk management.

In a QRA, risk can be defined as the combination of the likelihood (i.e. frequency) and severity (i.e. consequence) of Major Accident Events (MAE); in our case, this typically involves Loss of Containment (LOC) events for hazardous materials.

Hazardous Event Outcomes

Hazardous event outcomes such as fires, explosions and toxic dispersion are quantitatively assessed, and each event is assigned with frequency (in terms of annual frequency of occurrence, based on historical data) and consequence (in terms of harmful footprint distance) values. These represent the risk profile of an MAE.

Risk Summation

Risk summation is performed by taking the risk profiles of all potential MAEs within a facility and overlaying them on a geographical map concerning the facility layout and location of the various release sources (e.g. process/ storage equipment, handling operations, etc.), which can be imagined as placing layers one by one on top of each other on a map, with each layer representing the risk contribution from each MAE for each location. The overall facility-wide risk profile is simply the cumulative summation of each of these layers, typically illustrated in the form of various risk contours/ profiles.

Risk Contour

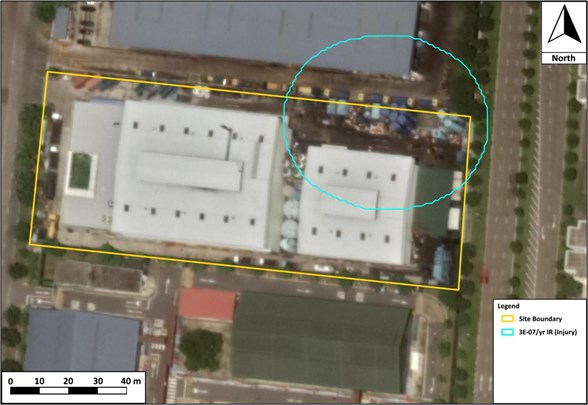

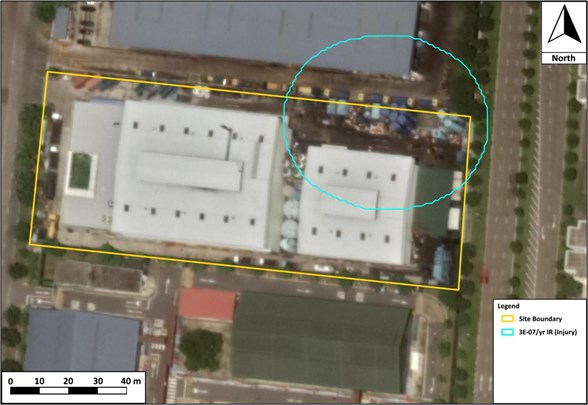

Figure 1: Typical Risk Contour Diagram Generated in a QRA

A risk contour is an illustration representing a specific risk level; in the case of the figure above (Figure 1), the risk level is 3E-07 per year. The region inside the risk contour (shown by the light blue line) has risk levels greater than 3E-07 per year, while the area outside the risk contour has risk levels below 3E-07 per year.

Singapore QRA Guidelines

In Singapore, QRA studies are subject to regulatory approvals based on risk criteria published by the Major Hazards Department (MHD) in the Revised QRA Guidelines, which define acceptance criteria for specific risk levels for several types of risk profiles.

Types of Risk Major Hazards

Individual Risk (IR) is the frequency at which an individual may be expected to sustain a given level of harm from the realisation of specified hazards. For the Singapore Revised QRA Guidelines, IR (Fatality) and IR (Injury) are considered. Additionally, IR (Fatality) for on-site occupied buildings is regarded as a separate criterion for each building.

Cumulative Escalation (CE) risk is also considered and refers to an IR equivalent for structures to differentiate between risk to systems and danger to humans. CE is modelled in the same way as IR from the frequency analysis and consequence modelling results.

The key difference between each risk profile type is the weights assigned to different harm levels, which correspond to the type of harm considered for the specific risk profile. For example, IR (injury) has more significant weightage given to lower thermal radiation levels for fire events than IR (Fatality), as a person exposed to a relatively lower thermal radiation from a fire may suffer injury due to burns but may not be severe enough to cause fatality. CE risk, which pertains to risk to structures, does not assign any weightage to toxic dispersion events as poisonous hazards.

These weights are used as modifiers to the frequency value of the respective harmful footprint calculations. Conceptually, for a given MAE, typically, we would expect to experience greater harm levels closer to the release source or hazardous event centre.

Thermal radiation intensity, explosion overpressure and flammable/toxic gas cloud concentrations gradually decrease as it moves further away from the source based on fluid type and prevailing atmospheric conditions. Hence, this is expressed through risk weightage.

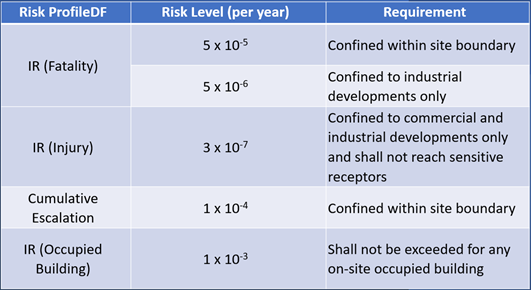

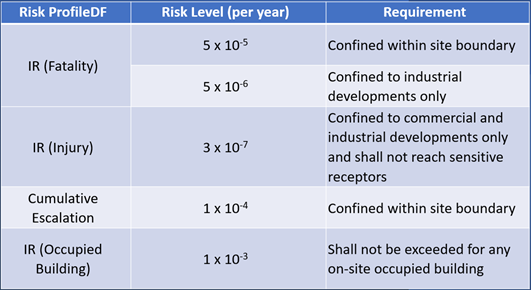

The QRA risk acceptance criteria stipulated in the Revised QRA Guidelines are listed in Table 1 below.

Table 1: Singapore QRA Risk Acceptance Criteria

In Singapore, the primary use of the QRA for regulatory authorities is for land use planning. The focus of the QRA risk acceptance criteria is essentially on impacts on off-site populations and installations identified as sensitive receptors, which can be seen from the requirements for specific risk profiles and levels to be confined within the site boundary (e.g. 5E-05 IR (Fatality) or 1E-04 Cumulative Escalation risk levels) or restricted from impacting certain land use types or sensitive receptors.

Regulatory agencies such as Singapore Civil Defence Force (SCDF), National Environment Agency (NEA), Ministry of Manpower (MOM) and JTC Corporation may also request operators to consider and assess safety and mitigation measures in place to reduce the size of risk contours to minimise the impacts to off-site areas, to safeguard existing populations in the site vicinity and to minimise potential future land use restrictions on neighbouring greenfield sites.