16 June 2023

ILS is a unified and iterative approach to the selection, management and performance of technical activities required to influence operational and equipment requirements and design specifications, and then to provide required operational phase support at optimum cost – delivering the benefits of increased operational availability and decreased lifecycle cost.

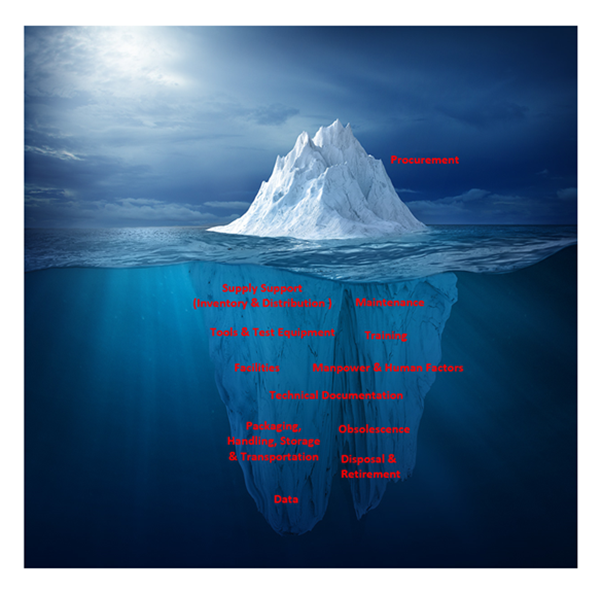

Costs through life contributes to a considerable part of the total acquisition and support investments:

Defence Standard 00-600 has been the statement of Ministry of Defence (MOD) requirements for ILS for many years, having evolved from comparable practices in the USA. However, it’s a dated methodology, requires bespoke application and is no longer considered best practice. For example, the ILS application through Def Stan 00-600 is specific to the UK MOD and is not used internationally; the term logistics has negative connotations and is often seen as an expensive optional extra or a “nice to have”, done by what we call “loggies”; traditional ILS standards were designed to deliver from a contractor to a military in-house support solution and only had detailed processes to support activities up to Logistic Support Date.

Consequently, the UK MOD are pursuing a new initiative, under the auspices of the Chief of Defence Logistics and Support, to reframe is to bring the focus back to the integration of all support elements, through-life, optimising operational availability of equipment at an optimal lifecycle cost. This is underpinned by a data model. It’s an enabler to achieving the broader principle of Strategic Asset Management and a move away from poor reputation that ILS sometimes carries because of poor application. IPS is built on the internationally recognised “S-Series” set of specifications that major primes and organisations around the globe are committed to. This means easier contracting, more integrated data management and sharing commitment to standards maintenance.

IPS is based on outputs – that is, delivering optimised availability at an optimised whole life cost. It’s built upon a set of standards, namely the adoption of the ASD’s S-Series ILS Specifications.

Key elements have been restructured and grouped to ensure greater integration – IPS covers all the ILS elements that were captured in Defence Standard 00-600 such as technical documentation, supply support, and obsolescence management. There is also an underpinning data model that will be integrated into the Support Target Architecture and Business Modernisation for Support (BMfS).

Finally, IPS will be responsible for the planning of many significant areas of Asset Management as per ISO 55000.

As the fifth operational domain, alongside air, land, maritime and cyberspace, the planning and delivery of an integrated product support package for space is even more critical. We need to consider the lack of ready access to the deployed unmanned systems and ensure that they have been assessed for operational availability as early as possible. Planning maintenance on an opportunistic basis or as part of any scheduled on-site support missions also needs to be factored. This could require specific in-service maintenance management and increased condition monitoring to enable ground staff to take appropriate action as defects or failures are highlighted as imminent.

A range of capabilities can be applied at any given point of the asset lifecycle, from component or equipment level, right up to programme or portfolio level. These capabilities are applied singularly or in combination, to realise a host of benefits such as optimised performance, cost reduction, cost control, or increased availability, reliability, and safety. This is in accordance with the customer’s priorities. At BMT, we have extensive experience in effectively delivering ILS / IPS solutions, and we can either act as an advisor, or takes responsibility for aspects of a customer’s asset base – reducing your overall management burden.

James is a Principal Managing Consultant for BMT. He is a senior consultant and manager with over 30 years of international experience of support and supportability issues.

Recent work includes consultancy to the MoD and many defence prime contractors, undertaking practical assignments to reduce life-cycle costs by improving supportability, sustainability, reliability and availability. Other responsibilities have included major roles in bid preparation, the generation and implementation of standards for ILS and ARM, and the provision of training courses in the UK and overseas. Previous to this, James’ experience included the management of the entire support package for a major UK/US joint venture project, resulting from involvement in the engineering management of present and future military projects.

Internal duties include being BMT’s Capability Manager for Through Life Engineering Solutions and line management of numerous senior members of staff.

BMT provides a comprehensive range of capabilities which can be applied at any given point of the lifecycle as illustrated below. Our expertise in these diverse fields is often world leading and can be applied from component or equipment level, to programme or portfolio level. These capabilities have been applied singularly or in combination, in order to derive benefits such as performance, cost reduction, cost control, availability, reliability and safety, in accordance with the customer’s priorities. BMT either acts as advisor or takes responsibility for aspects of a customer’s asset base – reducing the customer’s management burden.

BMT has successfully worked over many years to deliver cost-effective ILS / IPS solutions on a wide range of major platforms and systems across all environments. In summary, BMT take responsibility for the up-front IPS work (also known as “Design For Support” and “Design The Support”) to ensure that the design takes through-life supportability into account by assessing reliability, maintainability and human factors. We undertake modelling to ensure that the Operational Availability requirements will be met and deliver the underpinning analysis for the complete range of IPS elements including recommendations for supply support / spares provisioning, obsolescence management, technical documentation / maintenance instructions (based on Reliability Centred Maintenance), training needs analysis and technical documentation. This allows the Customer to focus on the design and manufacturing aspects, while remaining responsible for the delivery of the physical assets (e.g. spares and test equipment, training courses).

As an example, BMT was the main author of the set of ILS requirements for Project ADELIE, the Strategic Command (Defence Digital) project to generate the competitive contractual basis for, and then to deliver the technical support to, the Maritime and Land Deployed IT infrastructure, using Information Technology Infrastructure Library (ITIL) practices for service and asset management.

Furthermore, we are providing key inputs to the Engineering Support Transformation (EST) programme that will provide the capability, competency, and capacity to support the MOD to deliver across the Department to achieve significant financial and non-financial benefits. The Defence Support Strategy (DSS) Vision is that, within 15 years, Defence Support continually secures Support Advantage, enabling Defence to outpace, outwit and out-fight its enemies. EST is a key component of the DSS, enabling the strategic outcomes by building a better Engineering Support (Eng Sp) capability across Defence through the application of Strategic Asset Management principles in making a key contribution to managing availability and cost-effective logistic support.

Will Roberts

At BMT, we believe simulation is a critical enabler in overcoming these hurdles—de-risking development, accelerating innovation, and building confidence across the entire lifecycle of autonomous systems.

N/A

Get ready to dive deep into maritime autonomy as we bring you technical experts, insightful opinions, and unmissable discussions.

Dr Thomas Beard

Episode 3 of IMarEST’s Ship Energy & Environment podcast series, addressed the ‘Realities and Challenges of Alternative Marine Fuels. Dr Thomas Beard, Clean Shipping Lead explores the practical side of the 'big four' alternative fuels.

N/A

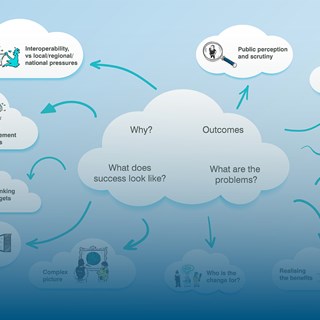

Delve into the top 10 challenges and interdependencies involved in selecting and adopting from the plethora of technological developments, and then embedding multiple new technologies in frontline UK policing, highlighting the multifaceted nature of this undertaking.