Forensic engineering and material failure analysis

We evaluate the suitability or interaction of materials to support design, maintenance, and investigations.

The suitability or interaction of materials is evaluated to support design, maintenance and forensic investigations. Metallurgical, weldability and mechanical issues are considered to ensure compliance with codes and standards, enhance construction and repair solution success and reduce the potential for in-service degradation and failure.

Experience and research-inspired expertise support vintage and modern material focused design and repair solution development, specification and documentation. Stress analysis, material behaviour (strength, fatigue and fracture), testing and analysis are employed in root-cause failure analysis.

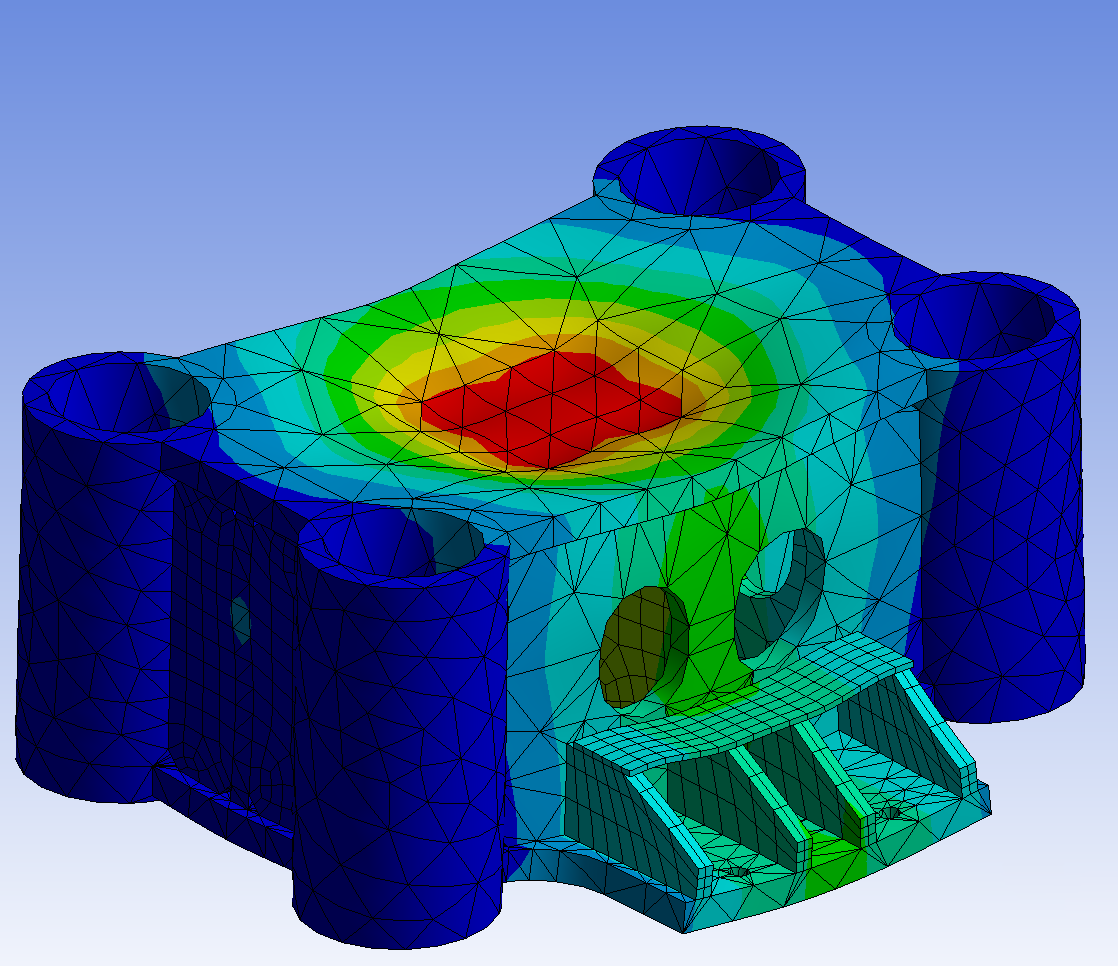

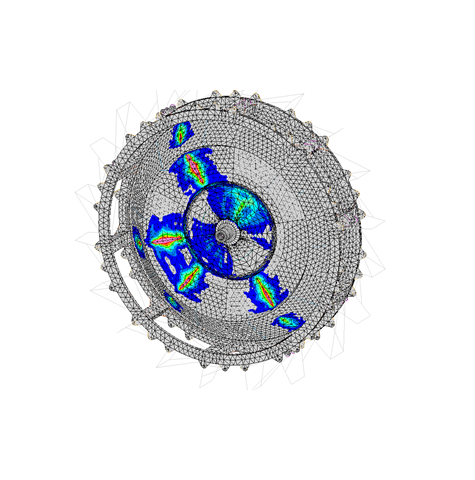

We use a range of powerful in-house and proprietary FEA software tools to analyse complex machine structures and components for stress, deflection, buckling, and fatigue, which provides an efficient and reliable way of identifying, addressing and mitigating problems to reduce downtime, increase safety and boost productivity. Our experience of applying FEA within the mining sector includes a state-of-the-art analysis of conveyor dynamics.

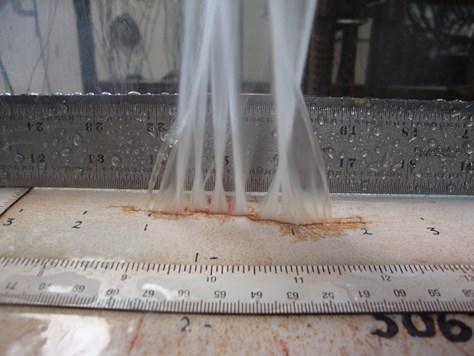

We have developed full-scale testing facilities and procedures to evaluate the strength and fatigue life of damaged or degraded (cracked, rusted, dented, buckled or wrinkled) pipe.

We also conduct leak rate testing to support the consequence evaluation of through-wall cracks. The facility is used extensively to create and test dents (simulated and removed from service) with and without corrosion and weld interaction to evaluate fatigue life.