AMT was then engaged to complete the Detail Design and ILS Package for the upgrade of the RO Plant system which involved the integration two new Reverse Osmosis Plants and upgraded seawater feed pumps. Other equipment integrated as part of the upgrade were a chlorine gas detection system including sensor, controller and sounder beacons, activated carbon filters for dechlorination of the fresh water flushing water, sand media filters for the feed seawater, sediment cartridge filters for feed seawater, a remineralisation filter for treating the RO product water and a Sodium Hypochlorite Dosing system for chlorination.

Electrical work included switchboard modifications and the addition of an auxiliary control box to integrate solenoid valves on seawater feed and freshwater flush lines to facilitate automatic operation and minimise ship’s crew operation and maintenance burden.

Installation was completed on HMAS Leeuwin in May 2019 and installation on HMAS Melville was completed in August 2019. AMT provided onsite production support in Cairns to facilitate resolution of issues and provide designer input to the process. This activity also provided the opportunity to enhance AMT personnel’s experience in managing production and installation issues with tight schedule constraints.

Final testing of the product water was completed at an external laboratory and met all applicable requirements.

The upgraded RO Plants provide the ship’s crew with a reliable source of potable water which is critical for maintaining capability and morale.

This project highlighted AMT’s capability in managing a variety of stakeholders including the End Customer, In-Service Support Contractor, Equipment OEMs and Installation Contractors to achieve an excellent outcome.

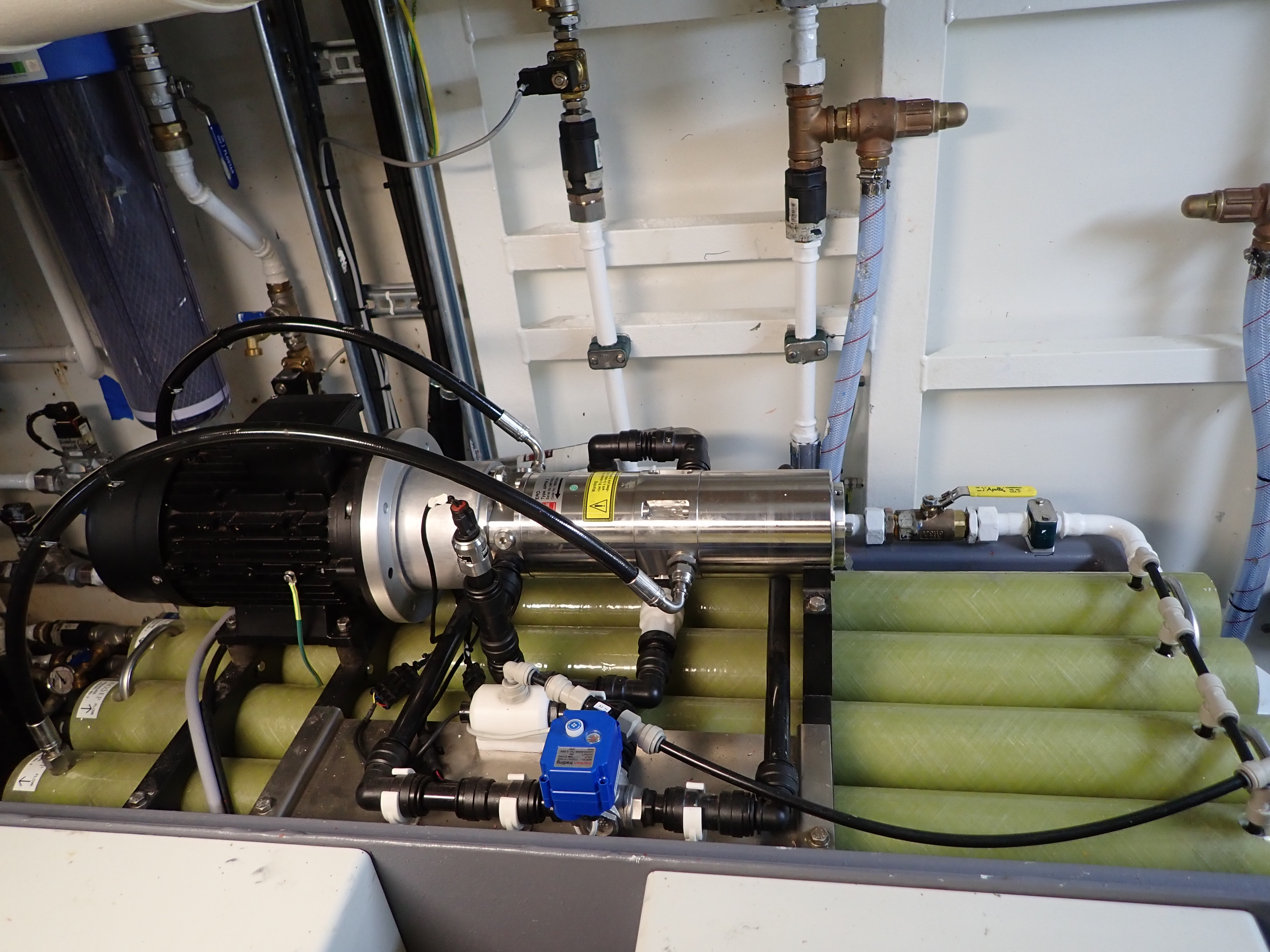

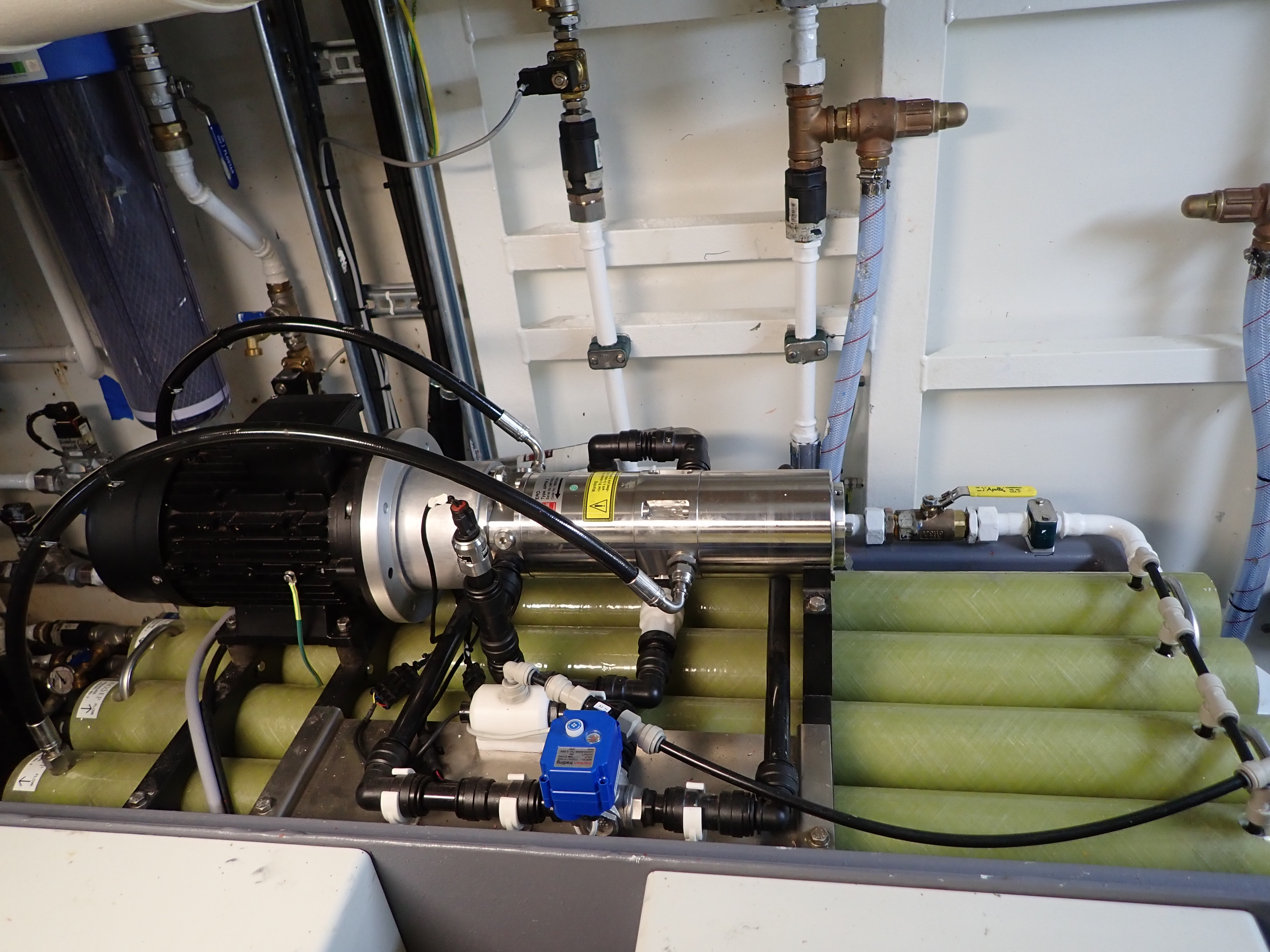

Seawater Feed Pumps

Filter Module

RO Plant High Pressure Pump and Membranes