Through-life engineering for pipeline transport

We apply engineering technical expertise to various asset integrity assurance and management programs, assisting you in meeting and exceeding industry standards, codes, and regulations.

We research innovative tools that support the design, construction and operations, in-service assessment, root-cause investigations, and repair solutions. The results of our efforts are often used to develop and advance industry standards, codes and regulations, and safety practices.

We develop practical and innovative solutions to engineering problems using advanced technical knowledge and expertise supported by experimentation and testing, field measurement, design, and analysis.

Our services:

We provide stress analysis, materials expertise, and fatigue and fracture assessment tools are combined to give design and in-service support for a wide range of pipeline and facility applications.

These services draw on our expertise with materials, welding, corrosion, mechanical, structural engineering, and code compliance to deliver remedial action plans, including complete engineering solutions, design, and material specifications, welding procedures, and concept and detailed construction drawing packages.

We have a wealth of experience supporting long- and short-term data acquisition and monitoring projects in the field, including developing plans, design, and assembly of data acquisition, storage, power, and reporting systems for on- or off-grid systems. Our instruments have been used for monitoring, processing, and reporting strain, temperature, speed, motions, and visual observations on pipelines and facility piping.

We have developed advanced analysis techniques to assess pipeline integrity for many anomalies, including pipe wall deformations, dents, and wrinkles. Fatigue, corrosion, and environmentally assisted cracking damage are considered with ILI data to establish optimal re-test/re-inspection intervals.

We provide conventional and advanced 3D continuum pipeline (pipe-soil interaction) modelling and expertise to deliver value in design, integrity assessment, and remedial action development. The effects of non-typical surface loading and hazards, including slope movement, faulting, or other ground movements, are assessed and forecasted while considering the pipeline's soil type, pipe geometry, alignment, and material properties.

We offer a wide range of pipeline design, construction, and operations support with a broad background in system design, analysis, hazard mitigation, and regulatory and code compliance. Our services in these areas provide practical and innovative solutions backed by more than 60 years of combined experience.

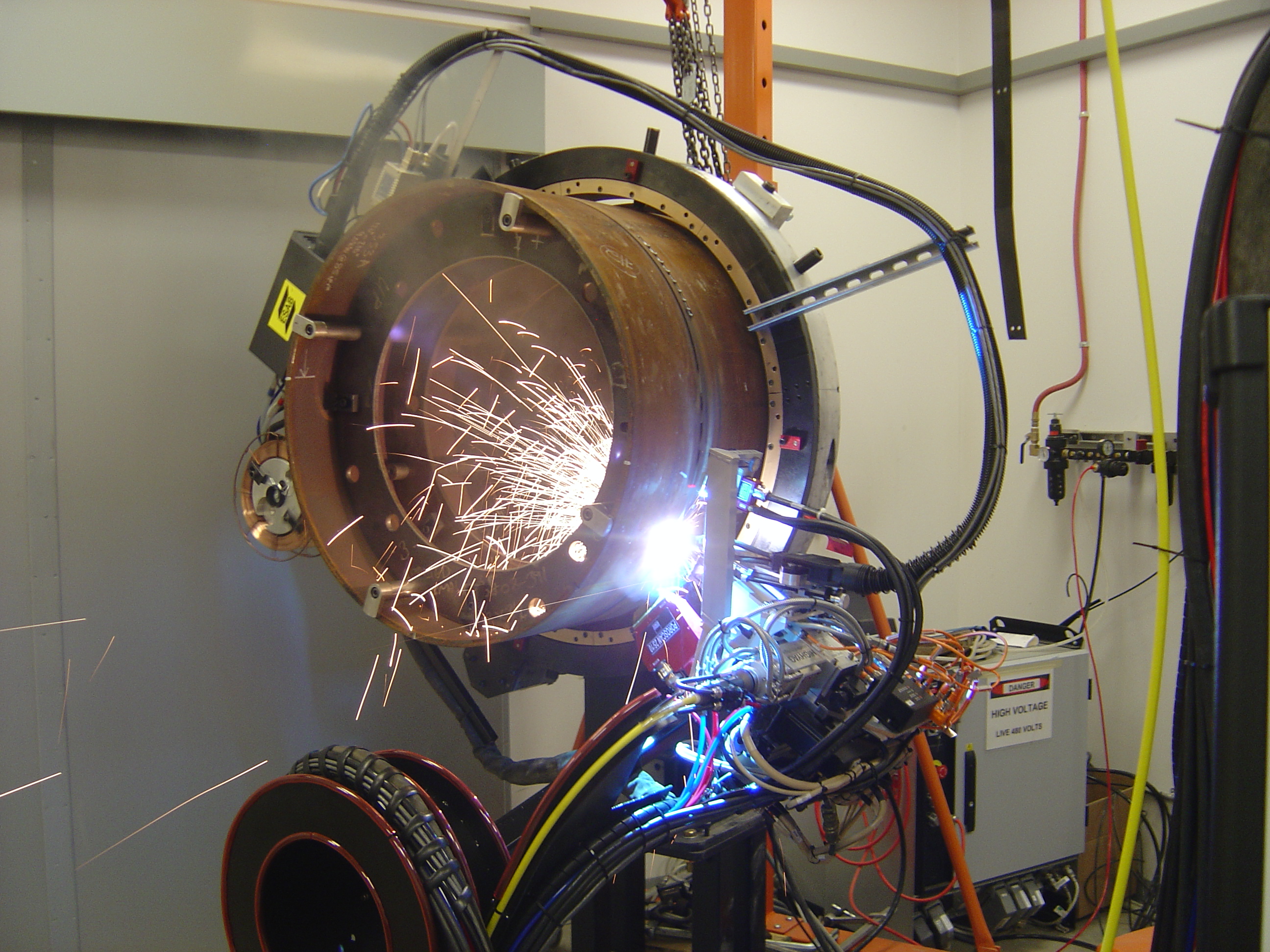

We have developed full-scale testing facilities and procedures to evaluate the strength and fatigue life of damaged or degraded (cracked, rusted, dented, buckled, or wrinkled) pipe.

The facility is used extensively to create and test dents (simulated and removed from service) with and without corrosion and weld interaction to evaluate fatigue life. We also conduct leak rate testing to support the consequence evaluation of through-wall cracks.

Our structural integrity assessment software analyses crack-like flaws for fatigue life and failure assessments using a range of operating loads and various industry standards (i.e., BS 7910, API 579, CSA Z662, NG-18, and others).

Unsupported pipeline span and river crossing scenario safety

Fatigue life evaluation of dented pipe with and without interacting features

Supporting material validation